De-icing

Ice prediction, real-time detection and automatic de-icing

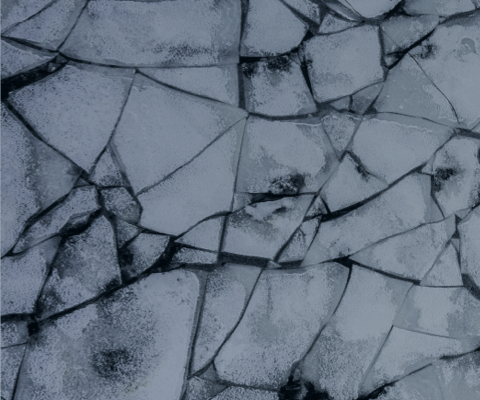

Reliable protection against ice formation

Advantages of our de-icing systems

- NSuitable for any object

- NProven technology

- NFree of chemicals

How it works

Coldsense de-icing systems combine risk assessment of icing with real-time detection and individually required heating power. The real-time and forecast data collected is fused using advanced AI algorithms and analyzed in seconds. If icing is imminent, the system automatically activates the de-icing module applied to the components.

Three-layer electrical heating elements are used for this purpose: the lowest layer serves as electrical insulation. The intermediate layer is conductive – there is a choice of various high-tech materials, including diamond-like carbon (DLC), indium tin oxide (ITO) and aluminum zinc oxide (AZO). The top layer is covered by a protective film that protects the heating elements from erosion, corrosion and moisture

Features

Uniform heating

Customized design of the heating elements

Anti-ice coating as a supplement

Upon request, we can also apply ice-repellent surface coatings to the components of your equipment and systems. Less ice and hoar frost settle on the coated surfaces – so less heating power is needed to keep your application ice-free. As a result, the de-icing system consumes less power or can be reduced in size.

More solutions against icing problems

More solutions against icing problems

Ice prediction

Precise risk assessment using artificial intelligence.

Ice detection

Fully automatic early detection of ice formation with alarm function.

Ice prevention

Innovative surface coating with ice repelling effect.